This site uses cookies for analytics and to improve your experience. By clicking Accept, you consent to our use of cookies.

MCD is present in France, Belgium, Switzerland and Luxembourg to carry out all your plate heat exchanger maintenance requirements.

YEARS OF EXPERTISE

CUSTOMERS IN 90 COUNTRIES

SEALS MANUFACTURED EACH YEAR

COMMITTED EMPLOYEES

Maintaining plate heat exchangers requires real expertise.

With a processing capacity of over 150,000 plates a year, our maintenance and reconditioning centre for plate heat exchangers, based at Guny in Hauts de France, gives new life to over 120,000 plates every year.

Today, major manufacturers and companies in France, Belgium, Luxembourg and Switzerland rely on us to maintain their heat exchangers, pasteurisers, sterilisers, refrigerators, heaters, evaporators, condensers and hot water exchangers.

Our ISO 9001 – 2015 and MASE-certified workshops provide a quality service at every stage of the maintenance of your plate heat exchangers.

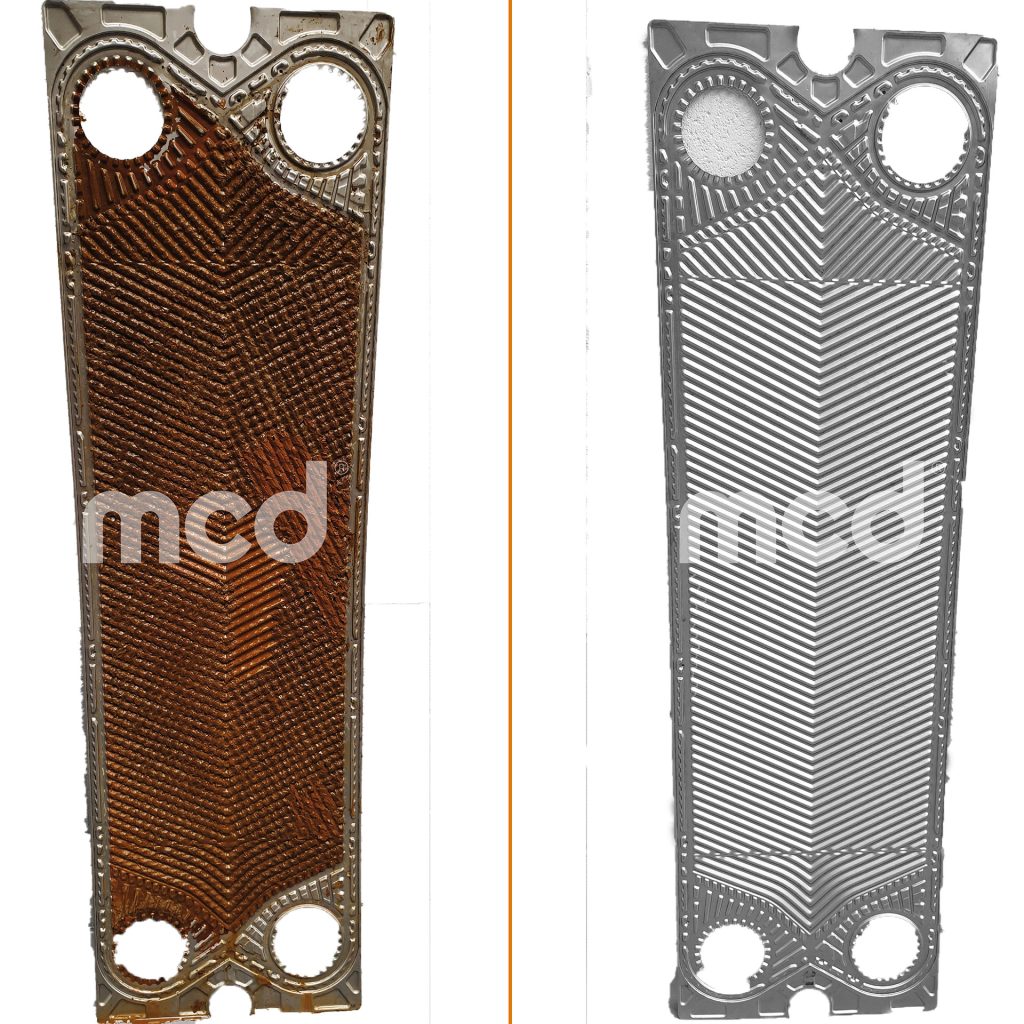

Our process for reconditioning and refurbishing your plate heat exchangers involves the following stages: reception, inspection of the plates, removal of gaskets, degreasing, cleaning of the plates (descaling, pickling and passivation of the plates), dye penetrant testing and detection of cracks, re-joining of the plates with MCD® gaskets, polymerisation by steaming.

As part of our commitment to offering you the best possible all-round service, we handle all makes and models of plate heat exchangers, in all types of alloy (stainless steel, titanium, tantalum, hastelloy) and in all sizes and thicknesses.

Each plate is received and identified by a qualified technician,

Exchanger data is entered into our ERP system to ensure full traceability of reconditioning operations.

Disjointing by soaking the plates in a liquid nitrogen bath (-196°C) in the case of glued joints or manual disjointing in the case of clipped joints.

Chemical cleaning of plates by immersion in soda and acid baths (specific baths for the food industry). Our new platesurface treatment line, linked to our waste water treatment plant, allows us to favour a closed circuit and guarantees ‘zero discharge’.

Penetrant testing of plates using a ‘penetrant/developer’ method in accordance with ISO 3452-2

Joining qualified panels with new MCD® joints, bonded with a two-component epoxy adhesive cured in a ventilated oven for bonded joints, or manually for clipped joints.

Strict individual inspection of each plate before packing, tidying up (in accordance with the assembly plan supplied by the customer) and reassembly of the plates in your exchanger. A Reconditioning Report (RRE) is also provided, detailing all the operations involved in reconditioning the exchanger.

To help you optimise the maintenance of your plate heat exchangers, we have developed four offers for each of the specific sectors of activity (global industry and food industry): Access, Classic, Comfort and Premium, giving you peace of mind when it comes to your maintenance operations.

Depending on the problems you encounter, your constraints, but also the condition of your plate heat exchanger, your seals and your plates, MCD can provide you with advice and expertise,

MCD provides you with advice and expertise to offer you the most appropriate solution.

Choosing MCD is your guarantee that your plate heat exchangers will last as long as possible!

Whatever the make and type of exchanger, MCD is committed to working alongside you to carry out all the operations required to prolong the performance of your exchanger.

Cleaning plates

Refurbishment of a plate heat exchanger frame