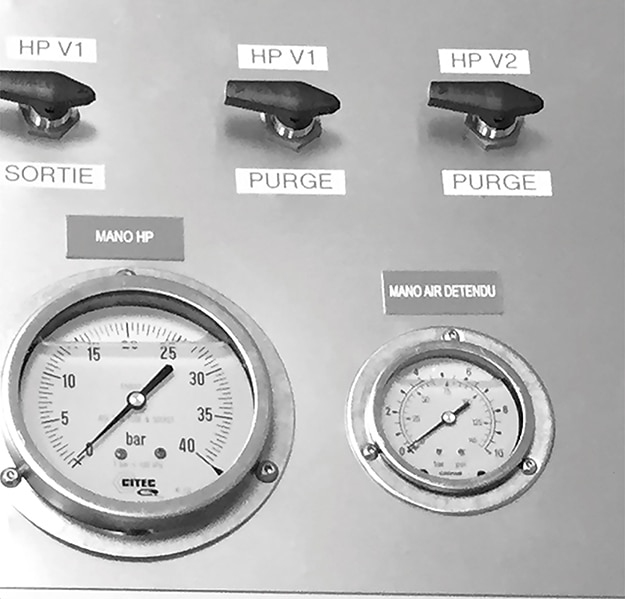

The O’Test™ consists of pressurising a circuit of a section with water ‘at least 3 bars’ for 15 minutes in order to check its internal tightness.

This site uses cookies for analytics and to improve your experience. By clicking Accept, you consent to our use of cookies.

MCD offers you a tailor-made service, on site or at our maintenance centre, for all processes and all makes of plate heat exchangers.

Developed by MCD over the last twenty years, integrity testing and auditing by MCD are now recognised because they meet production and downtime constraints, offer fast and reliable results and guarantee a level of detection compatible with quality and safety standards, particularly in the food industry. Discover our range of integrity tests by MCD®!

MCD is present in France, Belgium, Switzerland and Luxembourg to carry out all your plate heat exchanger maintenance requirements.

YEARS OF EXPERTISE

CUSTOMERS IN 90 COUNTRIES

SEALS MANUFACTURED EACH YEAR

COMMITTED EMPLOYEES

In the presence of a fluid, a pressure differential or a contaminating element such as bacteria, any through crack in a heat exchanger plate presents a potential risk of contamination between fluids (food risk, chemical risk, etc.).

Controlling processes and guaranteeing the integrity of plate heat exchangers is therefore a growing quality priority within companies.

We can meet all your requirements, enabling you to :

The O’Test™ consists of pressurising a circuit of a section with water ‘at least 3 bars’ for 15 minutes in order to check its internal tightness.

The benefits?

Identification of through cracks greater than 50 μm

Identification of through cracks greater than 50 μm

Simple and easy to use

Simple and easy to use

Short downtime, without opening the exchanger

Short downtime, without opening the exchanger

Data recording and retrieval

Data recording and retrieval

Issue of the O’test certificate

Issue of the O’test certificate

Diagnosis of corrective maintenance if necessary

Diagnosis of corrective maintenance if necessary

The BUL’Test™ consists of injecting a miscible tracer gas into one circuit of one section of the exchanger, and detecting by sniffing the presence of gas in the second circuit in air circulation.

The benefits?

Identification of through cracks down to 30 µm

Identification of through cracks down to 30 µm

Simple and easy to use

Simple and easy to use

Short downtime, without opening the exchanger

Short downtime, without opening the exchanger

Data recording and retrieval

Data recording and retrieval

Issue of the BUL’test certificate

Issue of the BUL’test certificate

Curative and/or predictive maintenance diagnostics if necessary

Curative and/or predictive maintenance diagnostics if necessary

The INT’Test™ integrity test involves injecting a tracer gas into a section of the exchanger, at different pressure levels, and sniffing to detect the presence of gas in the second vacuum circuit.

The benefits?

100% test guarantee by checking the state of the heat exchanger by opening it

100% test guarantee by checking the state of the heat exchanger by opening it

Highly accurate results, with through-crack detection down to 20 µm

Highly accurate results, with through-crack detection down to 20 µm

Quick read-out of results

Quick read-out of results

Very low stress on the plates

Very low stress on the plates

Data recording and retrieval

Data recording and retrieval

Issue of the INT’test certificate

Issue of the INT’test certificate

Curative and/or predictive maintenance diagnostics if necessary

Curative and/or predictive maintenance diagnostics if necessary

The ALL’Test™ solution consists of checking the general condition, the effectiveness of the cleaning in place and analysing all the wearing parts of your heat exchanger. This audit is completed by an INT’test integrity test.

The benefits?

Thorough inspection of all equipment

Thorough inspection of all equipment

Systematic replacement of all ring seals

Systematic replacement of all ring seals

Examination completed by an INT’test, and therefore detection of through microcracks down to 20 µm

Examination completed by an INT’test, and therefore detection of through microcracks down to 20 µm

Issue of the INT’test certificate

Issue of the INT’test certificate

Advice by MCD on the maintenance operations to be carried out in the short and medium term, based on the audit and the results of the INT’test

Advice by MCD on the maintenance operations to be carried out in the short and medium term, based on the audit and the results of the INT’test

Facilitating arbitration and decision-making to justify and plan technical shutdowns at the right time: vision of potential risks

Facilitating arbitration and decision-making to justify and plan technical shutdowns at the right time: vision of potential risks

Optimising and controlling maintenance costs

Optimising and controlling maintenance costs

If you would like to carry out an integrity test by MCD® for your exchanger, or if you have any doubts about the solutions on offer, we can help you make the right choice.

Our experts are available to advise you.

An innovative range of tests tailored to every need

Carried out by highly qualified technicians

Safe operations (MASE)

Support and monitoring of your exchanger (predictive maintenance)

A maintenance centre unique in Europe to refurbish your heat exchanger

Carry out your integrity test by MCD®.